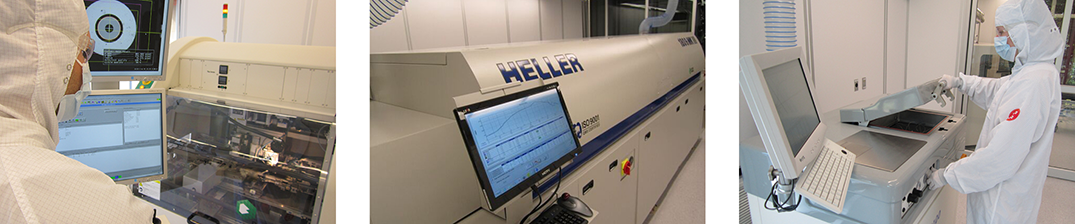

DIE ATTACH SPECIFICATIONS

• Epoxy die attach, flip chip, sintering, eutectic attach, multi-chip module

• X/Y placement accuracy: ±7μm @ 3 sigma

• Theta placement accuracy: ±0.15° @ 3 sigma

• Die thickness down to 20μm

• Speed: up to 7,000 units per hour

• Integrated dispense

• Material presentations: grip ring and film frame (for wafers up to 300mm), waffle pack, Gel-Pak

• Substrates: FR4, ceramic, BGA, flex, boat, lead-frame, waffle pack, Gel-Pak, JEDEC tray

SOLDER REFLOW SPECIFICATIONS

• Accommodates 18” wide boards and substrates and maximum clearance of 2.2”

• Tunnel length of 105” includes 9 heating zones each with independently controlled top and bottom heaters

• Maximum temperature 450 °C with PID temperature control ± 1°C per zone and ± 3° cross-belt temperature tolerance

• Internal controlled cooling zone 30” length includes 3 cooling zones with top and bottom cooling

• Balanced flow of air or nitrogen capable of producing controlled atmospheres less than 25 ppm O2

• CPK & SPC data and alarm logging with timed download and profile printout capability